In electronics product design, reference designs play an essential role in guiding engineers toward successful outcomes. These designs provide a structured framework, showing how components should be connected and the appropriate values to use for optimal performance. Designing schematics purely from imagination can be challenging and prone to errors, especially when working on complex circuits. Reference designs help simplify this process by offering a proven starting point.

However, while reference designs are incredibly helpful, it’s crucial to ensure they come from reliable sources, such as component manufacturers, reputable design firms, or trusted technical communities. Using poorly sourced or outdated reference materials can lead to suboptimal results and even design failures.

This article explores how to effectively utilize reference designs to create robust schematics that meet your design requirements.

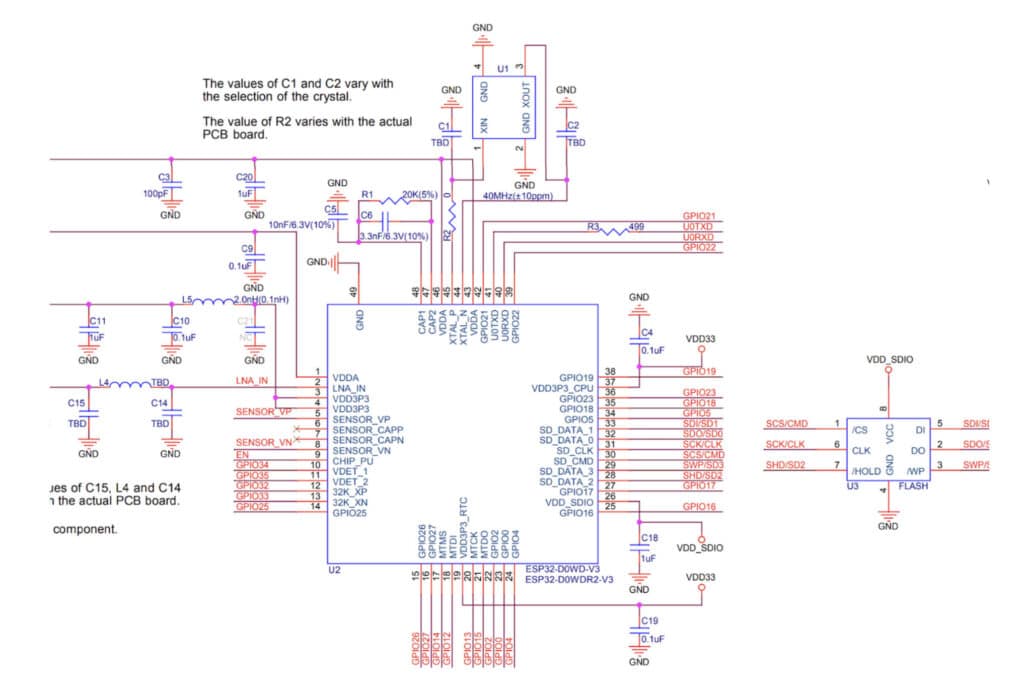

Reference designs serve as blueprints for creating reliable circuits. They are often created and tested by component manufacturers or industry experts to demonstrate the proper use of specific components or modules. These designs save time, reduce the chance of errors, and ensure adherence to industry standards.

For instance, a power supply reference design from a regulator IC’s datasheet can guide you on the proper placement of decoupling capacitors, feedback resistors, and grounding. This ensures stable voltage regulation without requiring extensive trial and error.

To make the most of reference designs, it is essential to analyze them carefully and extract relevant information. Below are some key aspects to focus on:

Examine how components are connected in the reference design. Look at:

Pay attention to the resistor, capacitor, and inductor values in the reference design. These values are chosen based on specific performance requirements, such as:

Identify important connections that impact circuit performance, such as:

By understanding these elements, you can adapt the reference design to your specific application while ensuring it performs reliably.

Reference designs are rarely a perfect match for your project and must often be customized. Here’s how to adapt them effectively:

Adjust values to meet the unique requirements of your circuit. For example:

Some reference designs may include unnecessary components for your application or omit components that are critical for your use case. For instance:

While reference designs are valuable tools, improper use can lead to costly errors. Below are common pitfalls and how to avoid them:

Copy-pasting a reference design without understanding its purpose can lead to unexpected issues. Always analyze the design and verify its suitability for your application.

A reference design complements the datasheet but does not replace it. Always cross-check the reference design with the datasheet to ensure the component is used within its specifications.

Reference designs are often generic. If your application has unique requirements—such as operating temperature, power constraints, or regulatory compliance—ensure the design is modified accordingly.

When used correctly, reference designs offer numerous advantages, including:

Reference designs provide a ready-made starting point, which significantly reduces the time spent on schematic creation and troubleshooting. By following pre-tested configurations, you can quickly progress through the design process without the need for extensive trial and error.

Since reference designs are extensively tested and verified by manufacturers, they adhere to best practices for circuit design. This ensures that your schematics are built on a solid foundation, reducing the risk of errors or failures in the final product.

Studying reference designs allows engineers, especially beginners, to gain valuable insights into industry-standard practices. This experience enhances their ability to create robust schematics and fosters a deeper understanding of how components interact in a circuit.

Reference designs simplify the design process, reduce errors, and accelerate development timelines. However, to use them effectively, you must carefully analyze the design, tailor it to your specific requirements, and validate it through simulation and prototyping if need arises. Additionally, always ensure your reference comes from a reputable source and complements the datasheet for the components being used.

By understanding and applying reference designs effectively, you can create robust and reliable schematics while improving your knowledge and skills in electronics design.