Creating effective electronics schematics is necessary for successful circuit design and implementation. A well designed schematic serves as a clear guide for review, troubleshooting, and collaboration. However, common mistakes can lead to confusion, errors, and inefficiencies.

A well-designed schematic can streamline the development process, reduce errors, and ensure compliance with industry standards. This article talks about the common pitfalls that designers face when creating electronics schematics and provides practical guidance on how to overcome these challenges, ultimately enhancing the schematic design process.

Mistake:

Failing to establish a clear ground reference can lead to misunderstandings and potential circuit failures, particularly in complex designs where multiple ground points may exist.

Solution:

Always define a single ground reference in your schematic. Use a distinct ground symbol (often represented as three horizontal lines) and ensure all components that require grounding are connected to this point. This practice simplifies troubleshooting and ensures consistent performance throughout the circuit.

Mistake:

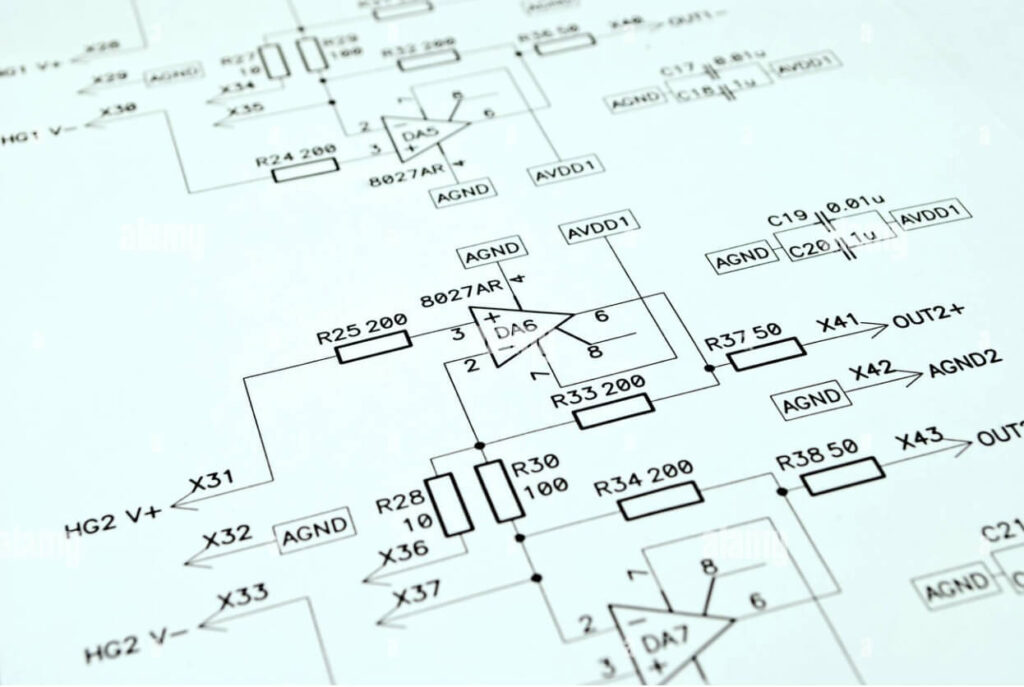

Using non-standard or inconsistent symbols can confuse anyone reading the schematic. This includes variations in symbols for the same component, leading to misinterpretation.

Solution:

Adhere to standard symbols as defined by industry standards (e.g., IEEE or IEC). Familiarize yourself with these symbols and apply them consistently throughout your designs. Many schematic design software packages include libraries of standard symbols to simplify this process.

Mistake:

Leaving out the values for resistors, capacitors, and other components creates ambiguity, making it difficult for others to understand your design intent.

Solution:

Always include component values directly on the schematic. Clearly label resistors (e.g., R1, R2) and capacitors (e.g., C1, C2) along with their respective values. This practice facilitates quick comprehension and aids in future modifications or troubleshooting.

Mistake:

An overcrowded schematic can become confusing and challenging to read, leading to errors in interpretation and design.

Solution:

Aim for a logical layout with adequate spacing between components. Group related components together, and use off-page connectors for complex designs that require multiple pages. This organization helps maintain clarity and allows the reader to follow the flow of the circuit easily.

Mistake:

Not considering the specifications of components (such as voltage ratings, power dissipation, and tolerance) can lead to functionality issues and even circuit failure.

Solution:

Before finalizing your schematic, verify that all components meet the necessary specifications for your application. Research component datasheets and understand the operational limits to ensure reliability and performance.

Mistake:

Inadequate labeling of wires and connections can result in confusion, making it difficult to trace signals and understand the schematic’s functionality.

Solution:

Use clear, descriptive labels for all wires and connections. Labeling can include designators that indicate the type of signal (e.g., Vcc for power supply, GND for ground) and any relevant notes about the connection. This practice helps anyone reviewing the schematic to understand its layout and function quickly.

Mistake:

Omitting comments or annotations can leave users in the dark about specific design choices or the purpose of certain components.

Solution:

Utilize comments and annotations to explain complex sections of your schematic. This could include design rationale, notes on component selection, or any specific instructions for assembly. Annotations provide valuable context, especially for those who may be unfamiliar with the project.

Mistake:

Skipping the simulation phase can lead to unforeseen issues during the actual implementation of the circuit.

Solution:

Before finalizing your design, you can use some circuit analysis software, such as CADY Solutions, to test your schematic. CADY Solutions offers robust simulation capabilities that enable you to identify potential problems, including:

Simulations can save time and resources by allowing you to troubleshoot issues virtually before physical implementation.

By incorporating this into your design process, you can significantly reduce errors, costs, and project delays.

Effective schematic design is a fundamental skill in electronics engineering that directly impacts the success of projects. By being aware of common mistakes and implementing the solutions outlined above, you can create clearer, more effective schematics.

A well-designed schematic not only aids in design and troubleshooting but also facilitates collaboration with others, ultimately leading to better project outcomes.