In electronics design, the choice of components plays a pivotal role in determining the performance, reliability, and cost-effectiveness of a product. Selecting the right components is more than just a technical decision; it requires balancing three critical factors: cost, quality, and availability. This balance ensures that the final design not only meets functional and performance requirements but also remains feasible to produce and scale over time.

In this article, we will explore these three factors in depth and provide actionable strategies for achieving this balance effectively.

Cost is often the first consideration in component selection, especially when working within budget constraints. However, it is important to approach cost strategically to avoid sacrificing quality and availability.

One key insight in cost analysis is understanding the difference between unit cost and total cost at scale. For instance, a component might appear cheaper when purchased in small quantities, but another component may have a significant price advantage when procured in bulk. This is particularly relevant for high-volume production runs, where even small cost differences per unit can translate into substantial savings.

To effectively manage costs, engineers should:

Ignoring the broader implications of cost can lead to budget overruns or the need to redesign a product mid-project due to unsustainable expenses.

While cost is a critical factor, quality should never be compromised. Poor quality components can lead to system failures, decreased reliability, and increased warranty claims—all of which are far costlier in the long run than the initial savings from choosing low-cost alternatives.

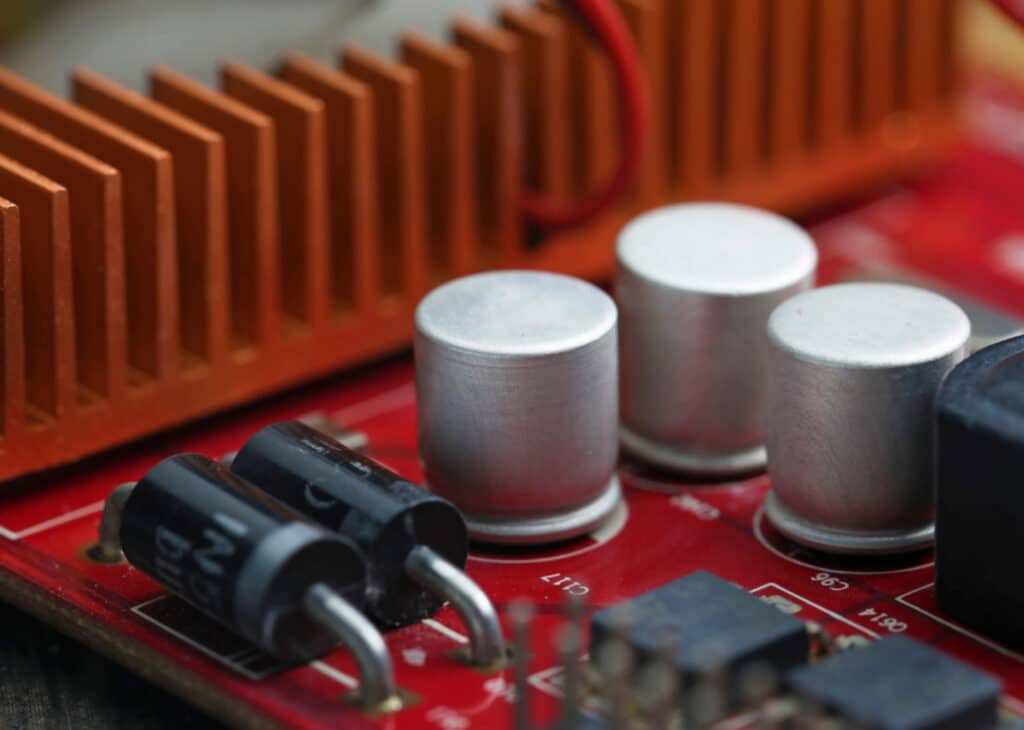

One essential aspect of assessing quality is understanding the operational environment of the system. Selecting a component without considering the intended environment can result in severe performance degradation over time. For example, a component designed for consumer electronics may not withstand the harsh conditions of industrial or automotive applications. In such environments, factors like temperature fluctuations, humidity, vibration, and electromagnetic interference (EMI) become critical. Using components that are not rated for these conditions can cause them to degrade prematurely, leading to system failures.

To ensure quality, engineers should:

Even the highest-quality and most cost-effective components are useless if they are unavailable when needed. Availability encompasses factors like stock levels, lead times, and long-term supply chain stability. Recent global events, such as the semiconductor shortage, have underscored the importance of prioritizing availability in component selection.

Designers often face challenges related to:

To mitigate these risks, engineers should:

Balancing cost, quality, and availability requires a holistic approach. These three factors are interconnected, and optimizing one often impacts the others. For example, prioritizing low cost may lead to quality compromises or limited availability. Similarly, focusing solely on quality can increase costs and limit options for readily available components.

A practical way to achieve this balance is through trade-off analysis. Engineers should:

Effective component selection begins with thorough research. Engineers should leverage tools like online sourcing platforms (e.g., Digi-Key, Mouser, Octopart) to compare prices, check stock levels, and evaluate component specifications. Reviewing datasheets and application notes is essential for understanding component capabilities and limitations.

When planning, it’s important to:

Working with reliable suppliers is crucial for ensuring quality and availability. Building strong relationships with trusted distributors and manufacturers can provide advantages such as priority access to stock and better pricing.

To manage suppliers effectively:

As production scales, the impact of component selection becomes more pronounced. Designing for scalability involves:

Scalability ensures that the product can adapt to changing market demands without requiring significant redesigns.

Modern tools and resources simplify the component selection process, enabling engineers to make informed decisions efficiently. Key resources include:

Platforms like Digi-Key, Mouser, and Octopart allow designers to:

These platforms streamline the research process and help identify the best options for specific requirements.

Manufacturer and distributor websites often provide valuable resources, including application notes, design guides, and case studies. Online forums and communities can also be a goldmine for practical advice and troubleshooting tips. Engaging with these resources ensures that engineers stay informed about the latest trends and solutions.

Balancing cost, quality, and availability in component selection is a complex but essential part of electronics design. By considering the interdependence of these factors and adopting a strategic approach, engineers can create designs that are not only technically sound but also commercially viable. With proper planning, research, and supplier management, designers can overcome challenges and deliver reliable, scalable, and cost-effective products.

The key to success lies in understanding the trade-offs and making informed decisions that align with both technical requirements and business objectives. By following the strategies outlined in this article, engineers can navigate the challenges of component selection and build a strong foundation for their projects.