Imagine investing weeks into designing an electronic circuit, only to realize that a critical component is unavailable or your design doesn’t fit the constraints of the manufacturer you chose. This scenario is more common than you might think, especially among beginner designers eager to jump straight into creating their first project.

Electronics design is both an art and a science, requiring not just creativity but also meticulous planning. Each step you take determines whether your design will succeed or fail. To avoid pitfalls and ensure a smoother journey, it’s essential to lay a strong foundation before picking up a single component. In this article, we will explore five critical aspects that every electronics designer must know before diving into their project. These insights can save you from costly mistakes and set you up for success. Let’s get started!

Designing without a clear understanding of the problem is like navigating without a map. Lack of proper knowledge about the problem you’re solving can lead to design failure. A good design starts with identifying the need and ensuring that your solution addresses it effectively.

If you don’t fully grasp the requirements of your project, you risk overengineering, underengineering, or solving the wrong problem altogether. For example, imagine designing a power supply for a device that requires 12V, but you mistakenly assume it needs 5V. This oversight would render your design unusable and waste valuable time and resources.

By starting with clarity, you build a solid foundation for the rest of the design process.

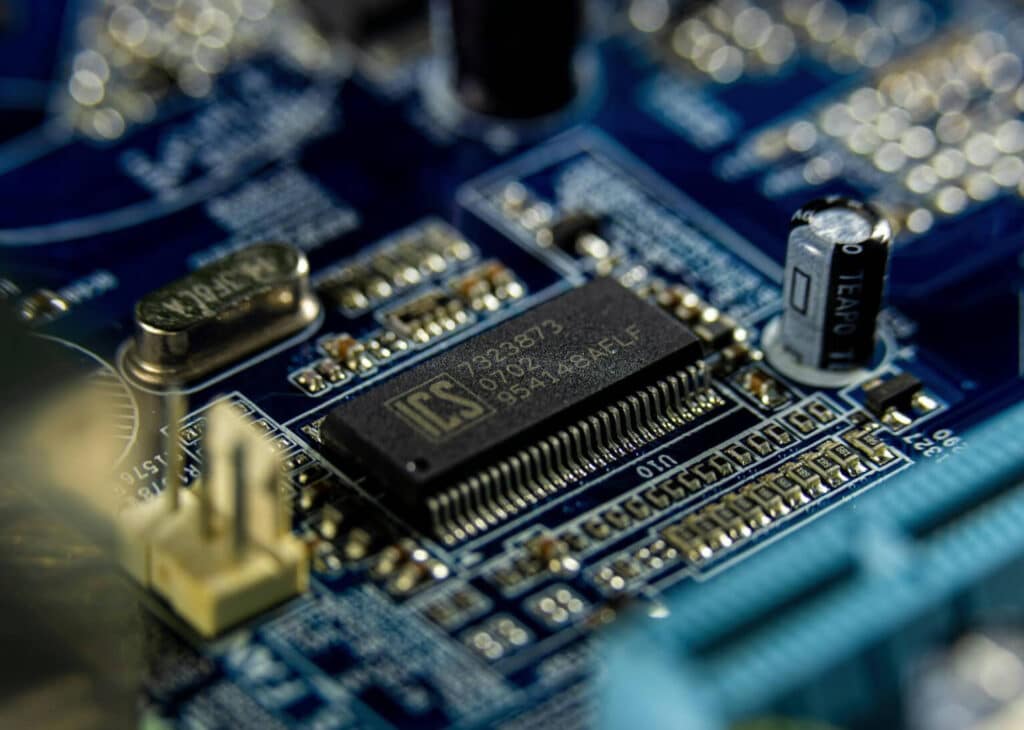

To jump right into design isn’t the best option. Checking if the components are available in the market is very important because it ensures that there isn’t any delay in production time. Availability directly impacts the feasibility and timeline of your project.

Many beginner designers skip this consideration, excitedly picking components based solely on technical specifications or cost without checking their availability. This often leads to redesigns or delays when a key component turns out to be out of stock or discontinued.

A beginner designing a smart home sensor might select a microcontroller with impressive features but fail to realize it has a 12-week lead time. This oversight would halt production and derail the project timeline.

Proper component selection saves time and prevents unnecessary headaches during production.

Every electronic design relies on a stable power supply. Without proper power management and circuit protection, your design may suffer from instability or, worse, permanent damage.

Before you start any design, you need to know who will manufacture and produce your board so that you can design within their constraints. DFM ensures that your design can be efficiently and cost-effectively produced.

Failing to account for manufacturing constraints can lead to increased production costs or unusable boards. For instance, designing traces that are too narrow for your manufacturer’s capabilities might result in broken circuits.

A design that’s easy to manufacture and test saves time and money while improving reliability.

Good documentation ensures that your design can be understood, replicated, or modified by others (or even by you) in the future. Version control prevents chaos when multiple iterations of your design emerge.

With proper documentation and version control, you ensure your design’s longevity and adaptability.

Electronics design is a rewarding process, but it demands careful planning and attention to detail. By understanding the problem, choosing the right components, planning power management, designing for manufacturability, and keeping thorough documentation, you lay the groundwork for success.

Start every project with these principles in mind, and you’ll not only avoid common pitfalls but also create designs that are functional, reliable, and ready for production. Remember, a little extra preparation at the start can save you countless hours later. Good luck with your next design adventure!